Hardware Options for Rotary Laser Cutting Systems

Standard Head – CP Scan – Galvo Head – Hold-Down Foot Plate – CP RotaDots CP Milling Tool & Metal Screw Detector – Camera System

Every Cutlite Penta laser cutting machine can be equipped with a number of hardware solutions, in order to perform even the most complex processes. Thanks to a wide range of hardware, a laser system can be configured and customized according to your needs.

Standard Head

Focusing Head with focal length lens, with surface follower device (Hold-Down). Adjustable focus within 80mm from working table; low pressure functioning of shielding gas.

CP Scan – Galvo Head

Galvo head is used for the rapid creation of logos, designs, coding information, etc., on the dieboard for identification purposes.

Galvo head is used for the rapid creation of logos, designs, coding information, etc., on the dieboard for identification purposes.

See the high speed etching process on our You Tube channel by clicking here.

Hold-Down Foot Plate

The foot-plate system is equipped with an electronic sensor that can detect any differences in thickness or deformation of the wood sheet, thus preventing contact with the material being cut (and avoiding uneven cuts at different points).

CP RotaDots

Lighting Laser Device for positioning the fixing screws of the die curve in pre-assembly phase, external to the cutting system.

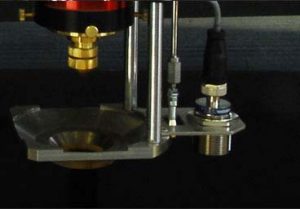

CP Milling Tool & Metal Screw Detector

Milling unit: equipped with automatic toll change, drawn rom a 3-position warehouse (up to a maximum of 6 on request).

The system also includes a metal screw detector for screws that fix the die-board to the wood support, so as to avoid contact between the screw and the milling tool.

The system also includes a metal screw detector for screws that fix the die-board to the wood support, so as to avoid contact between the screw and the milling tool.

Accuracy of the milling depth is also guaranteed by the presence of a foot-place of the material being worked, which always ensures the right position of the cutting head by compensating for any material thickness differences.

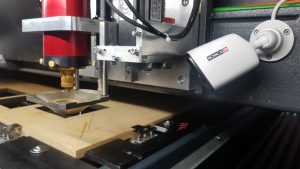

Camera System

Vision system (CCD camera) for recognition of positional references (fiducial marks) for automatic position correction (offset and rotation) on the workpiece.

Vision system (CCD camera) for recognition of positional references (fiducial marks) for automatic position correction (offset and rotation) on the workpiece.

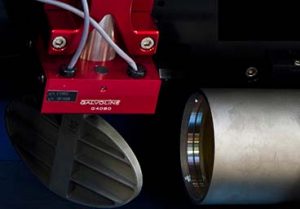

CP RotUp

The Rotary Off-Line mounting system “CP-RotUp” allows easy and fast preparation of the next rotary shell, boosting up the production time and drastically cutting down the down times due the screwing of the flanges on the rotary shells.

A pneumatic clamping support the operator locking the shell on top of the flanges in a very accurate way, then a user-friendly multiple laser pointer allow to retrieve the exact location where the metal screw must be inserted. A must for every